Many businesses today, especially in fields such as medical, automotive or aerospace, will not purchase inadequately marked products from suppliers as verification and quality are imperative. The systems used in marking include a wide variety of marking tools which emboss, engrave, etch, stamp or otherwise create designs on surfaces of metals, glass, plastics, marble, paper and other materials. Read More…

Is your facility in need of high performance dot peen machines? Our top of the line machinery is guaranteed to meet all of your needs. We are your worry-free provider of identification systems. We will work with your team to implement our products into your business and our services are beyond compare. Our company has proven ourselves as an industry leader!

Matthews Marking Systems is a global supplier of printing systems and consumables for product identification, branding, and traceability solutions. With over 160 years of marking and coding experience, we’ve established a global reputation as a premier innovator and manufacturer in the marking and coding industry.

Laser Marking Technologies LLC has served the marking machinery and laser cutting services industries for over 20 years. Our years of experience and advanced technology make us a leader in marking machinery and laser-cutting services.

At Automark, our team of experts is ready and willing to tackle any of your challenging assignments. We supply marking systems for a multitude of industries such as medical, cosmetic, industrial, automotive, and more. All of our machines are manufactured to the highest quality, offered at a competitive price, and are guaranteed to last. Give us a call and a representative will speak with you...

A world market leader in the field of marking machinery, Alpine Metal Tech is a “full-liner” for all marking & reading technologies throughout the process chain in every sector of the marking machinery industry. We offer products such as laser marking equipment, marking systems, hot stamping machines, marking tools & embossing machines. Customers come first with our company. Contact us to...

Isotech offers a full range of Fiber, C02, UV, Green, MOPA, Nanosecond, Picosecond and Femtosecond laser systems for marking, cutting and welding of many substrates. Isotech offers both standard systems as well as fully automated or custom systems depending on your specific requirements. Integrated, automated solutions with conveyors, palletized pick and place, rotary dial tables, hoppers, and...

More Marking System Manufacturers

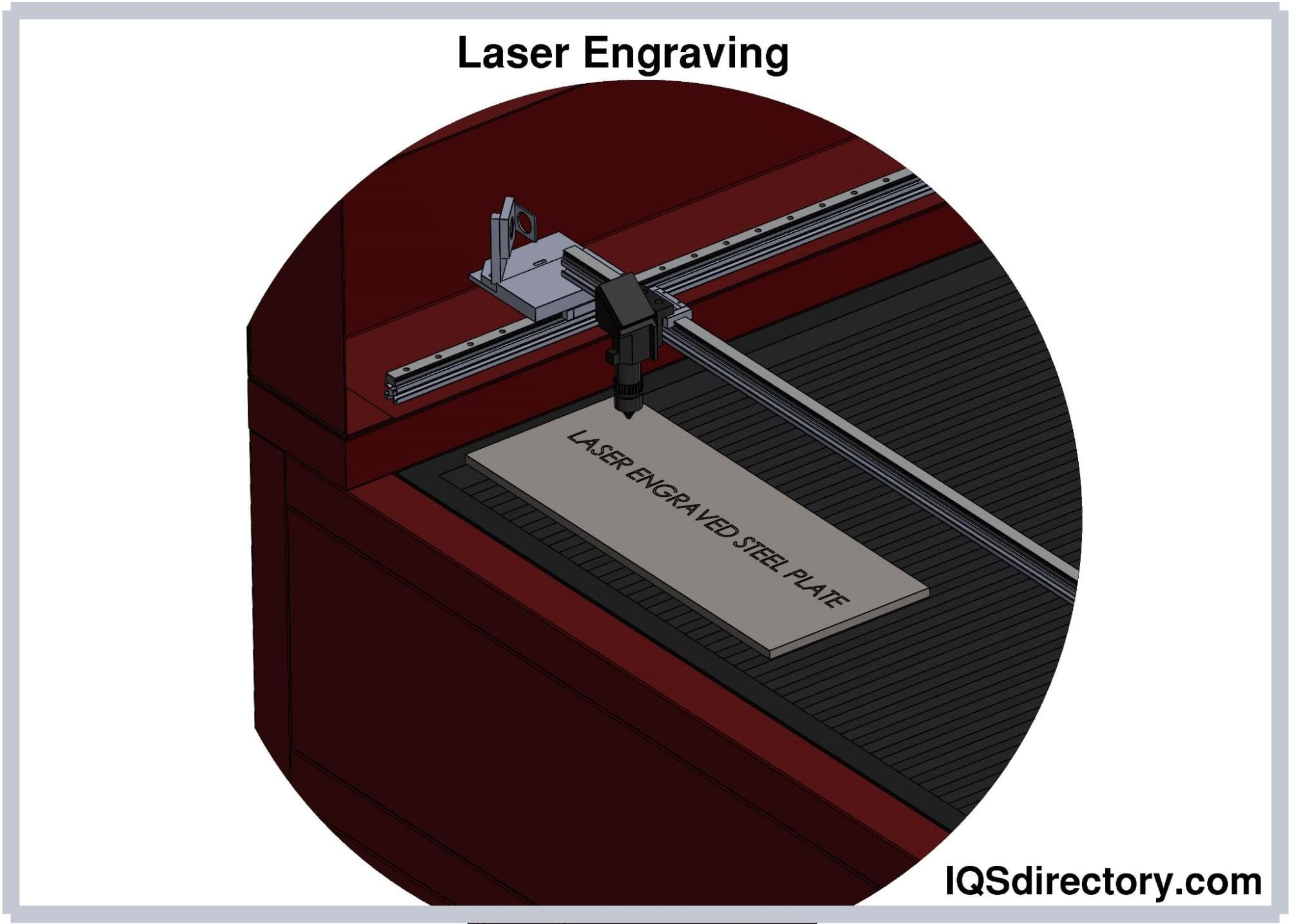

Many techniques are employed in the process of marking, including laser marking, press marking, roll marking, stylus marking and nameplate marking. The method of marking will be chosen based on the material being processed, the intended use and lifespan of the material, and the amount of detail required in the labeling mark. Marking systems will vary according to the requirements of the customer.

For precision machinery required in applications such as medical or aerospace, methods of marking that do not alter the surface of an object are necessary. Other applications that are more rugged, and use more durable materials may require engraving or embossing marking methods in order to ensure the longevity of the identifying mark.

Systems can be designed for manual use, low or high volume needs, or integrated as part of an existing automated production system.The different types of marking systems vary widely. Laser markers use laser wavelengths to mark an object, and as they do not require tool bits or engraving edges are considered a sustainable method of marking.

Selecting a laser marking system includes finding the correct wavelength for the material and surface being marked; coated metals and uncoated metals require different wavelengths in order for successful marking to occur. Press marking is not suitable for more delicate objects as it uses a hydraulic ram to create an impression, or imprint, on a part.

Roll marking uses rollers or type holders that press designs in either round or flat materials, while rotary marking is used mainly for circular or spherical parts. Stylus marking is most commonly used in image creation as many sizes of marking heads are able to be used. They are rapidly pressed or dragged across the material distorting the surface and creating the design. These machines may be handheld, although larger stylus systems are also used for high-volume part marking, or for heavier metals and materials.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services