Marking machinery is any machinery or tool used to create markings on parts and products. Markings such as these include designs, images, logos, identification codes, and more. Part marking has a wide range of applications. First, it can be used to value products, maintain quality control, deter counterfeiting, ease the returning of products, and create increased customer recognition. Read More…

Is your facility in need of high performance dot peen machines? Our top of the line machinery is guaranteed to meet all of your needs. We are your worry-free provider of identification systems. We will work with your team to implement our products into your business and our services are beyond compare. Our company has proven ourselves as an industry leader!

Matthews Marking Systems is a global supplier of printing systems and consumables for product identification, branding, and traceability solutions. With over 160 years of marking and coding experience, we’ve established a global reputation as a premier innovator and manufacturer in the marking and coding industry.

Laser Marking Technologies LLC has served the marking machinery and laser cutting services industries for over 20 years. Our years of experience and advanced technology make us a leader in marking machinery and laser-cutting services.

At Automark, our team of experts is ready and willing to tackle any of your challenging assignments. We supply marking systems for a multitude of industries such as medical, cosmetic, industrial, automotive, and more. All of our machines are manufactured to the highest quality, offered at a competitive price, and are guaranteed to last. Give us a call and a representative will speak with you...

A world market leader in the field of marking machinery, Alpine Metal Tech is a “full-liner” for all marking & reading technologies throughout the process chain in every sector of the marking machinery industry. We offer products such as laser marking equipment, marking systems, hot stamping machines, marking tools & embossing machines. Customers come first with our company. Contact us to...

Isotech offers a full range of Fiber, C02, UV, Green, MOPA, Nanosecond, Picosecond and Femtosecond laser systems for marking, cutting and welding of many substrates. Isotech offers both standard systems as well as fully automated or custom systems depending on your specific requirements. Integrated, automated solutions with conveyors, palletized pick and place, rotary dial tables, hoppers, and...

More Marking Machinery Manufacturers

Many everyday items, including credit and debit cards, packaging boxes, and electronic components, are marked by specialized machines. As the need for precise product identification increases, industries like automotive, medical, and aerospace demand well-marked products from their suppliers.

Beyond practical uses, marking systems are also popular for decorative purposes. People often mark jewelry, writing utensils, greeting cards, wood trim, cables, and glass sculptures. Manufacturers employ marking machinery on a wide variety of materials, such as metal, paper, plastic, wood, leather, glass, fabric, and textiles.

History of Marking Machinery

Humans have been marking items since long before the advent of modern machinery. One of the earliest examples of engraving dates back between 430,000 and 540,000 years ago, seen in a chiseled shell discovered in Indonesia. Following this discovery, the next oldest artifacts found are ostrich shells with engraved bandings, likely created around 60,000 BC, found at the Diepkloof Rock Shelter in South Africa. These shells were likely used by early humans as containers or cups for water. During the Upper Paleolithic period, which spanned from about 50,000 to 10,000 years ago, humans globally began engraving ivory and bone with depictions that reflected their daily lives and cultures.

Around the 1st Millennium BC, humans started metal marking using techniques like lost-wax casting and chasing, allowing for shallow grooves. It was during this period that they also began engraving gemstones for jewelry and decorative purposes.

During the early 1600s, Jacque Callot, a French printmaker, revolutionized the art of etching with his invention of the échoppe, an etching needle distinguished by its slanted oval point. This innovation enabled metalworkers and artists to replicate the bold, swelling lines typically reserved for engraving techniques.

During the 20th century, governments globally aimed to streamline markets and establish uniform standards for labeling machinery. For instance, in 1984, the European Union introduced the CE mark. Short for Conformité Européenne (European Conformity), this mark visibly identifies products and equipment that meet specified standards. Similarly, countries like the United States and Canada developed their own conformity marks, aligning with and adapting the principles of the CE mark.

Since then, marking technologies have advanced significantly. Today, they play a crucial role in creating intricate electronic markings. While handcrafted engraving and etching persists, CNC machinery largely dominates these tasks due to its precision and efficiency.

Types of Marking Machinery

Marking systems encompass a variety of machines designed to emboss, etch, stamp, or print designs onto diverse surfaces. These systems utilize a range of techniques and tools , including laser markers, press markers, dot peen machines, and nameplate markers. Additionally, they incorporate other specialized equipment such as embossing machines, engraving machines, roll or rotary marking devices, hot stamping machines, numbering machines, and etching machines.

Press markers, also known as presses, excel at creating rapid, enduring marks. However, they lack flexibility and require considerable setup time. Moreover, they are unsuitable for hard or fragile materials and can pose operational hazards.

Dot peen machines, alternatively called dot marking or pin mark machines, utilize a micro-percussion marking system to imprint objects with a series of closely spaced dots. This method employs a tapping pin for fast and precise marking, ensuring minimal stress on the substrate without material removal.

Nameplate markers, aptly named for their purpose, are tools utilized for imprinting or etching nameplates. Typically, these are employed for metal nameplates positioned on desks or displayed outside office spaces.

Embossing machines utilize heat and pressure to impress a three-dimensional image onto ductile materials such as plastic and leather. This process permanently deforms the material’s surface, imprinting product information. Credit cards, for instance, display raised numbers and letters through this method.

Engraving machines, designed to cut intricate grooves, excel particularly on tough materials such as metals, making them ideal for crafting jewelry.

Roll marking equipment employs cylindrical dies that are rolled physically onto the product for marking purposes. It offers a cost-effective alternative compared to equipment designed for high tonnage operations.

Hot stamp presses involve several key components: a stamping foil, a heated plate, and a metallic stamp or die. In operation, manufacturers heat the metallic stamp using the hot plate, then apply both the stamp and the foil onto the surface of the part intended for marking.

Hand stamping, performed manually, is a cost-effective and straightforward process that doesn’t necessitate costly equipment or highly skilled operators. However, it is labor-intensive and prone to inconsistencies.

Numbering machines are specialized marking devices designed to imprint sequential numbers onto papers, typically utilized for the purpose of legal documentation.

Printing machines serve the additional purpose of marking flat surfaces, typically using ink to create marks.

Industrial inkjet printers represent a larger-scale iteration of their household and office counterparts. They boast significantly faster printing speeds compared to various other marking technologies, yet their reliance on impermanent inks poses environmental hazards.

Pad printing machines enable the printing of 2D marks on 3D products by utilizing silicone pads to transfer images from a printing plate onto the product’s surface. They are commonly purchased by customers in industries such as electronics, toys, and medical equipment marking.

Chemical etching utilizes corrosive acids or bases to selectively remove material from a surface. The process typically includes five key stages: cleaning the surface, applying a mask, marking or scribing the desired pattern, etching to dissolve the exposed areas, and finally removing the mask. While cost-effective, chemical etching can yield inconsistent results, making it more suitable for less precision-critical applications or materials.

Plasma etching falls into two main categories: vacuum and normal-pressure types. Vacuum plasma, the more prevalent method, creates plasma from gasses like oxygen under reduced pressure to activate molding surfaces. While highly effective for surface modification, it operates in batches and prolonged processing times can degrade moldings.

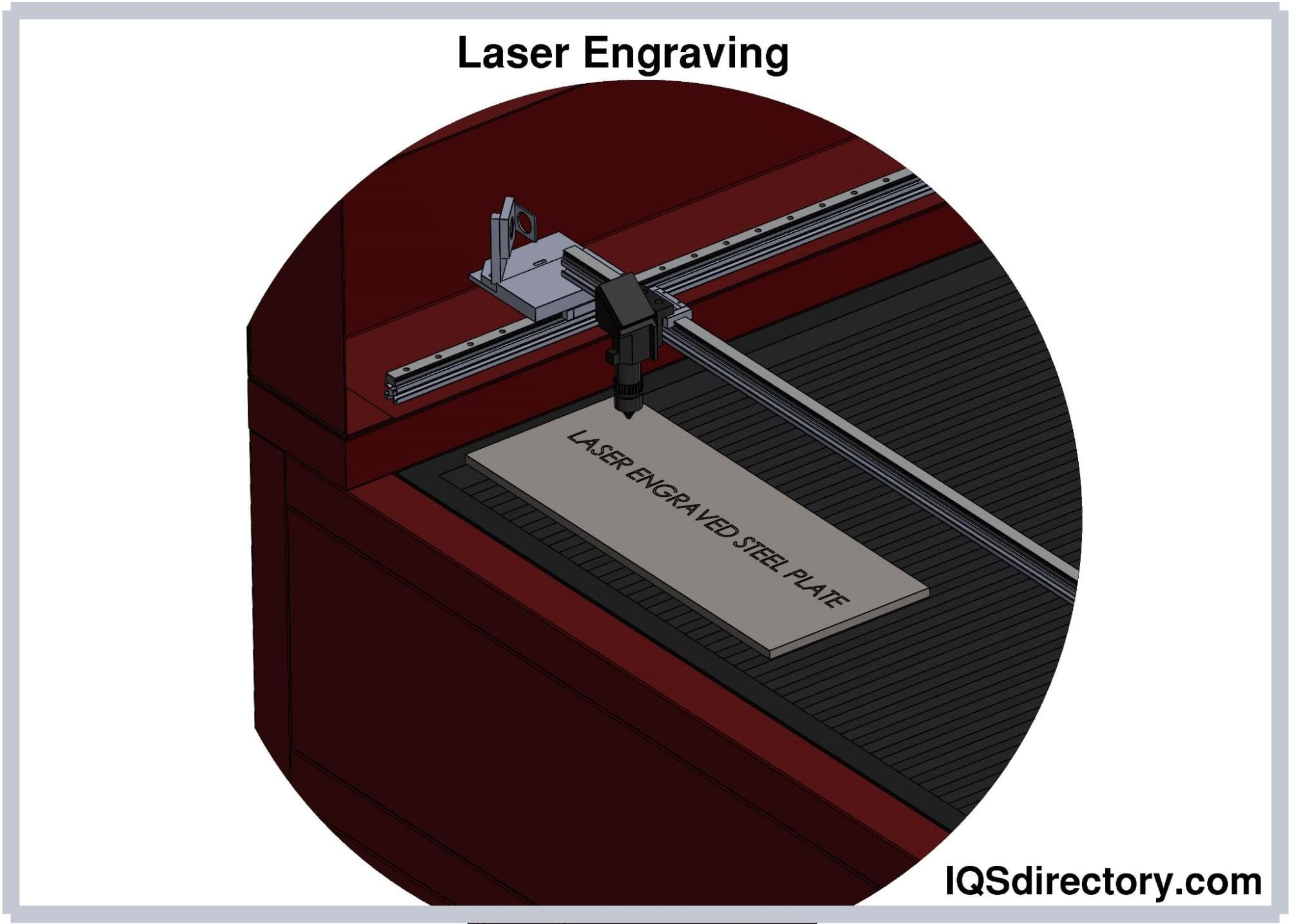

Laser marking utilizes a powerful beam of laser radiation, typically from a fiber laser, to directly imprint materials’ surfaces. The process categorizes laser markers based on beam wavelength, tailored to the material’s properties and responsiveness to laser energy. This technology engraves or etches designs permanently by focusing a concentrated light beam onto the material, ensuring lasting impressions that do not fade over time like ink or dyes. Automated modern machines facilitate its application for writing text, barcodes, or graphics on various materials.

How Does Laser Marking Work?

The laser, utilizing light amplification by stimulated emission of radiation, targets a surface directly. Through interaction with the material, the laser alters its properties, thereby causing noticeable changes to the surface appearance. The laser targets a precise section of the surface needing marking. Suitable materials encompass metals, plastics, foils, films, paints, and more. Marking techniques range from annealing and staining to foaming, engraving, and removal.

Types of Laser Marking Machines

Laser marking is achieved using specialized machines designed for the purpose. These machines utilize specific wavelengths of laser light tailored to different materials for effective marking.

Following are the three major types:

Fiber laser marking machines employ 1090-nanometer infrared lasers, ideal for marking metals and metal products. Their infrared wavelength allows them to penetrate opaque surfaces, making them particularly effective for materials that are not transparent. These machines excel in tasks such as annealing and engraving metal.

UV laser marking utilizes ultraviolet rays at a precise wavelength of 355 nm. Ultraviolet (UV) light possesses high absorptive qualities, making it ideal for cold marking applications. This method is particularly suited for materials with high reflectance, such as gold and copper, or those sensitive to heat typically generated during conventional laser marking processes.

CO2 laser marking machines are employed for marking paper, resins, rubbers, as well as transparent materials such as glass and certain plastics. With a wavelength system ten times longer than conventional lasers, these machines are ideal for materials that normal lasers cannot effectively absorb, especially transparent ones.

Advantages of Laser Marking

Laser marking offers more than just durable, abrasion-resistant markings. It enables traceability, making it straightforward to track items once branded or identified. This method produces minimal waste and is efficient, creating clear, easily visible marks. By providing unique identification and traceability, it effectively reduces risks associated with counterfeiting.

Laser Marking Applications

Laser technology has versatile applications, some of which are as follows:

Metals employed in jewelry possess delicate properties necessitating intricate designs, susceptible to damage from excessive heat. Laser marking emerges as the optimal solution in the goldsmith industry, offering cold marking capabilities. This method enables swift and precise labeling of numerous products, ensuring compliance with industry regulations for long-term traceability.

A finely tuned laser marker can make micro-cuts, slicing surfaces just a few millimeters thick with exceptional precision. Additionally, it enables photoengraving on metals, accurately reproducing images or photographs onto the desired surface.

Marking Machinery Equipment Components

Marking machinery typically incorporates various components, drawing from a common set of options. These machines often utilize specialized tools such as scribers, press stamps, steel stamps, rubber stamps, printing plates, and other marking instruments.

Scribers are integral parts of machinery designed to imprint marks onto materials. They are typically slender in shape and can be composed of materials such as metal, diamond, or lasers.

Press stamps, integral components of stamping machines, operate using either hydraulic or pneumatic power sources.

Steel stamps find application in scenarios with low production volumes. They imprint products by striking or pressing into a material, creating indentations for identification.

Hot rubber stamps closely resemble steel stamps, but they’re crafted from a heat-resistant rubber or silicone rather than steel plates.

Benefits

Marking machinery offers us many benefits. Firstly, it operates much faster, with greater accuracy and repeatability compared to traditional hand stamping. Secondly, it plays a crucial role in quality assurance by efficiently tracking parts throughout manufacturing processes. Thirdly, marking machinery is highly adaptable and can be customized to meet a wide range of requirements, ensuring manufacturers can tailor solutions precisely to their needs.

Marking Machinery Design and Customization

When designing marking machinery, manufacturers must consider several application aspects. These include the types of markings required (such as deep cuts, delicate decorations, or precise cuts for electronics), the materials of the products, the volume of production, the size of the system, integration into existing production systems, and adherence to conformity standards.

These application details assist in determining the type of marking system to design and the appropriate marking tools to install. For instance, if precise mark placement and alignment are crucial considerations, or if the marking needs involve handling a high volume of products, a comprehensive marking machine system is likely to be developed to meet those requirements.

Before determining which marking machine is appropriate for an application, one should consider the cost of spare parts, the maintenance complexity, the size of the marking system, and the integration difficulty with other production equipment and systems already in place.

Marking Machinery Safety and Compliance Standards

Markings play a crucial role, so acquiring marking machinery that meets rigorous quality standards is essential. It’s equally vital to maintain this equipment to ensure it consistently meets these high standards.

In the United States, all marking machinery must comply with OSHA safety standards. Internationally, adherence to standard directives from organizations like ISO (International Standards Organization) is crucial for your marking equipment. Moreover, machinery destined for use in the European Union or for producing goods bound for the EU must bear the CE mark. This mark serves as a quality assurance stamp, indicating that your equipment has passed rigorous testing according to official conformity assessment procedures, and meets all EU environmental, health, and safety directives.

Choosing the Right Marking Machinery Manufacturer

If you’re in the market for marking machinery, consulting with a specialist in this field is essential. To assist you in making an informed decision, we’ve compiled a list featuring the leading manufacturers of marking machinery available today. While we endorse all the manufacturers listed, it’s important to recognize that each offers unique strengths. To identify the best fit for your needs, take the time to review their profiles carefully. Assess which companies align with your requirements and budget. Narrow down your choices to three or four top contenders, then reach out to each one to discuss your specific application thoroughly. Leave no detail unexplored: cover budget considerations, deadlines, delivery requirements, and technical specifications. After these discussions, compare your notes and determine which manufacturer best meets your criteria.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services