Laser marking uses a focused laser beam to change the surface of a target. An oscillator emits the laser beam, which is scanned by a mirror (known as a scanning mirror) and focused on the target by modifying the surface using a focusing lens. As opposed to ink-based marking, which is more prone to abrasion, laser marking uses light to modify the target surface, and the marking is permanent. Read More…

Is your facility in need of high performance dot peen machines? Our top of the line machinery is guaranteed to meet all of your needs. We are your worry-free provider of identification systems. We will work with your team to implement our products into your business and our services are beyond compare. Our company has proven ourselves as an industry leader!

Matthews Marking Systems is a global supplier of printing systems and consumables for product identification, branding, and traceability solutions. With over 160 years of marking and coding experience, we’ve established a global reputation as a premier innovator and manufacturer in the marking and coding industry.

Laser Marking Technologies LLC has served the marking machinery and laser cutting services industries for over 20 years. Our years of experience and advanced technology make us a leader in marking machinery and laser-cutting services.

At Automark, our team of experts is ready and willing to tackle any of your challenging assignments. We supply marking systems for a multitude of industries such as medical, cosmetic, industrial, automotive, and more. All of our machines are manufactured to the highest quality, offered at a competitive price, and are guaranteed to last. Give us a call and a representative will speak with you...

A world market leader in the field of marking machinery, Alpine Metal Tech is a “full-liner” for all marking & reading technologies throughout the process chain in every sector of the marking machinery industry. We offer products such as laser marking equipment, marking systems, hot stamping machines, marking tools & embossing machines. Customers come first with our company. Contact us to...

Isotech offers a full range of Fiber, C02, UV, Green, MOPA, Nanosecond, Picosecond and Femtosecond laser systems for marking, cutting and welding of many substrates. Isotech offers both standard systems as well as fully automated or custom systems depending on your specific requirements. Integrated, automated solutions with conveyors, palletized pick and place, rotary dial tables, hoppers, and...

More Laser Marking Manufacturers

Laser Marking

Laser marking uses a focused laser beam to change the surface of a target. An oscillator emits the laser beam, which is scanned by a mirror (known as a scanning mirror) and focused on the target by modifying the surface using a focusing lens. As opposed to ink-based marking, which is more prone to abrasion, laser marking uses light to modify the target surface, and the marking is permanent.

Laser Marking On Metal

Metals can be marked with a laser using the black-annealed method, in which the laser produces oxidation. Metal is also marked by the engraving method, in which the laser is used to engrave deeply into the target surface. Every technique has a particular use.

Characteristics of Laser Marking

Black-Annealed (Oxidation) Marking

The laser beam's focus is changed when directed at the marking target so that only heat will be transferred. An oxide coating is created on the target's surface when heat is applied without etching it. This marking has a dark appearance and depicts a black marking.

White etching marking

A slightly removed portion of the metal surface reveals an uneven surface. This results in light reflecting unevenly, producing markings that appear white.

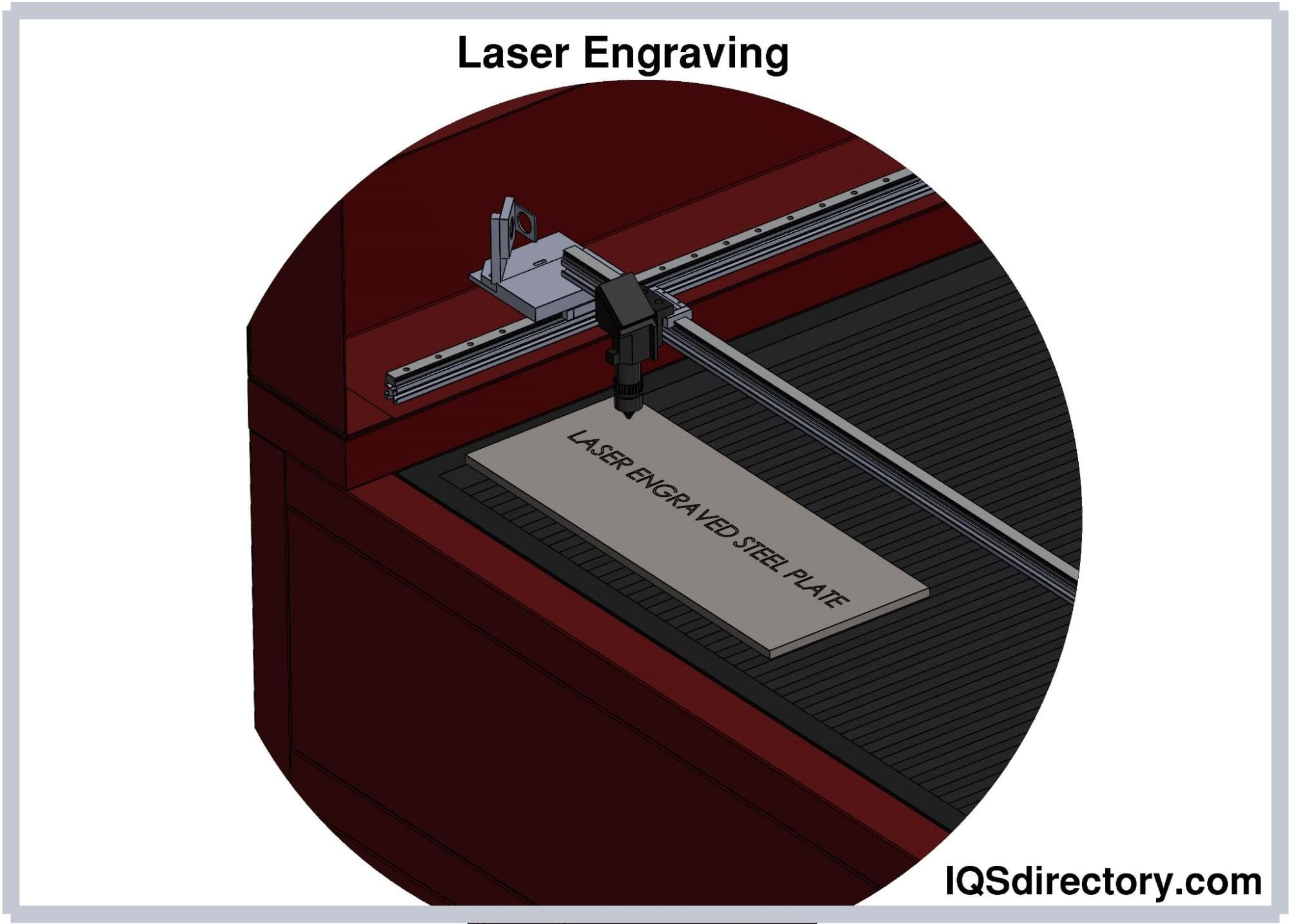

Engraving marking

The target surface is etched for marking by laser light, which illuminates the target's focal point. Increasing the engraving by increasing the number of laser irradiations can produce a deeply etched impression.

Laser Marking On Plastic

For marking plastic with a laser, there are three techniques:

- Foaming, where the laser causes bubbles.

- Chemical change, where the pigments in the plastic react with the laser.

- Carbonization, where a high-energy laser is used to cover the target surface.

Foaming

Bubbles are produced inside the substance when a laser irradiates the base material. These bubbles are hidden behind the base material's top layer, which gives them a white appearance. On darker base materials, foaming is more noticeable.

Chemical change

Color development results from a chemical change resulting from the laser light's interaction with the metal ions in the pigment of the base material. The look varies depending on the target's color and material.

Carbonization

The molecules of the element around the base material are carbonized and turn black when high energy is given continuously to the area. While the polycarbonate material on the right is translucent, when carbonized, it turns a stunning shade of black.

Laser marking on other materials

Other than metal and plastic, laser marking can be used to label various materials. Laser marking, for instance, is applicable on a variety of transparent and translucent targets in addition to pottery, paper, and wood. Targets with a surface coating that may be removed to reveal the underlying base material or painted surface are also suitable for laser marking.

Processing With Laser Marking

In addition to marking, lasers can be used for various processing tasks like cutting, drilling, and surface reforming. For example, target regions can be rapidly processed by scanning the light to the desired shape.

Cutting

The desired shape is cut during cutting by scanning the laser light to the designated location. This technique can be used to remove gates and burrs in addition to cutting complex forms effortlessly.

Surface reformation

This procedure removes a target's surface material, such as paint, film, or plating, using laser light. To strengthen the binding and stop any paste from flowing out, surface reformation also modifies the wettability of the surface material.

Drilling

Laser-based drilling creates a hole in a target by irradiating a single point with laser light, which causes melting and evaporation. Drilling holes as required for the application is feasible by adjusting variables like the laser's size and power.

Laser Marking Machine Operation

When using laser marking equipment, a device for correctly positioning the target is required. There are three different types of laser marking machines: stand-alone systems, which mark targets one at a time, indexing systems, which mark several targets at once; and inline systems, which mark targets as they are transported.

Laser Marking Machine Types And Features

It is possible to find several kinds of laser marking equipment, each with a unique laser wavelength best suited for a particular material or application. CO2, UV, and fiber laser marking devices are the three most common types of laser marking equipment.

Fiber Laser Marking

Fiber laser marking devices are IR (infrared) lasers because of their 1090 nm wavelength. Although fiber lasers may mark various surfaces, metal is the medium on which they work best. In addition, IR light is transparent to transparent surfaces, so fiber lasers cannot mark transparent surfaces despite their great power, making them ideal for engraving and annealing applications.

UV Laser Marking

UV lasers use a highly absorbent wavelength (355 nm) to label objects. UV lasers may "cold mark" materials without introducing additional heat stress because of their high absorption rate, especially those with high reflectivities like gold, silver, and copper.

CO2 Laser Marking

The wavelength of CO2 laser marking equipment is 10 times that of conventional wavelength systems. They work well for marking transparent materials, rubber, wood, resins, and paper (like glass and PET). A CO2 laser marking equipment, however, cannot mark metal since the laser light is not absorbed.

Choosing the Correct Laser Marking Manufacturer

To make sure you have the most beneficial outcome when purchasing Laser Marking from a Laser Marking Manufacturer, it is important to compare at least 5 or 6 Companies using our list of Laser Marking companies. Each Laser Marking Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Laser Marking business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Laser Marking businesses with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services